Manufacturing plants often bleed money without realizing where the leak started. Unplanned equipment failures, disconnected systems, and manual workarounds create a cascade of expenses that rarely show up on budget reports. These hidden costs accumulate quietly, eroding profit margins while production teams scramble to keep operations moving forward.

Companies serious about protecting their bottom line turn to a Rockwell Automation Integrator to identify and eliminate these financial drains. The specialists don’t just install equipment; they rebuild how information flows between machines, operators, and management systems. By connecting previously isolated components into a unified control environment, they create visibility into problems that were invisible before. The result is a manufacturing operation that runs leaner and responds faster to disruptions.

The Real Cost of Disconnected Systems

Siloed Operations Create Compound Inefficiencies: When production lines operate as separate islands, each running its own logic and protocols, inefficiency multiplies across the facility. Operators waste time translating data between incompatible systems, maintenance teams struggle to diagnose problems spanning multiple platforms, and managers lack the comprehensive view needed for informed decisions. This fragmentation turns simple issues into complex troubleshooting marathons that consume hours of productive time.

Hidden Expenses Beyond the Obvious: The financial impact extends far beyond visible downtime. Energy consumption spikes when systems can’t communicate optimal parameters. Raw material waste increases when processes run without real-time feedback loops. Labor costs balloon as workers compensate for automation gaps with manual interventions. Perhaps most damaging, production scheduling becomes unreliable, leading to missed delivery commitments and strained customer relationships that threaten long-term revenue.

Data Blind Spots Prevent Improvement: Disconnected systems generate isolated data sets that tell incomplete stories. Quality trends remain hidden when inspection results don’t connect to process parameters. Predictive maintenance opportunities slip away because equipment health signals never reach analysis tools. Production managers make decisions based on partial information, optimizing one area while unknowingly degrading another. This fragmented visibility keeps facilities trapped in reactive mode, addressing problems only after they’ve already caused damage.

How Strategic Integration Transforms Operations

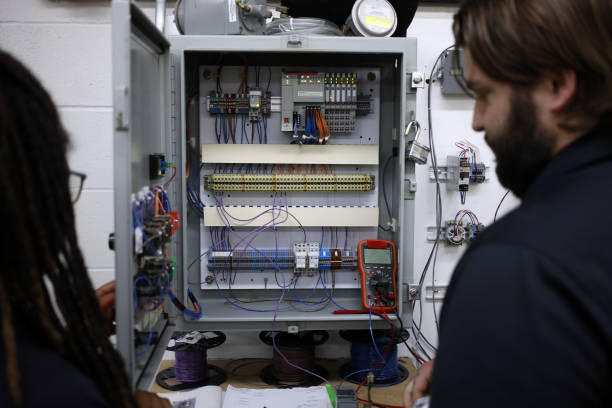

Unified Control Architecture Eliminates Redundancy: Integration specialists build frameworks where controllers, sensors, and human machine interfaces share a common language. This architectural approach eliminates the need for middleware patches and custom translation scripts that break during updates. Equipment communicates directly, reducing the points of failure that cause mysterious shutdowns. Maintenance becomes straightforward when technicians work with standardized configurations rather than piecing together documentation from multiple vendors.

Optimized Data Flow Enables Proactive Decisions: When information moves seamlessly from shop floor to enterprise systems, patterns emerge that were invisible before. Production supervisors spot efficiency dips before they become chronic problems. Quality engineers correlate process variations with final product characteristics in real time. Supply chain teams adjust purchasing based on actual consumption rates rather than forecasts. This connected intelligence transforms gut-feeling management into evidence-based optimization that compounds savings across every shift.

Reduced Complexity Lowers Operating Costs: A well-integrated system requires fewer specialized skills to maintain. Operators trained on one interface can manage multiple production areas. The engineering team spends less time firefighting compatibility issues and more time improving processes. Software updates roll out systematically rather than requiring individual attention for each disconnected component. These operational simplifications directly reduce the headcount needed to maintain production targets, freeing resources for growth initiatives.

Measuring Integration’s Business Impact

Integration delivers quantifiable improvements across several critical metrics that directly affect profitability:

- Unplanned downtime typically drops 30-40% as predictive analytics catch developing problems before equipment fails completely.

- Energy consumption decreases 15-25% when coordinated control logic eliminates redundant heating, cooling, and motor cycling.

- Labor efficiency improves 20-35% as operators manage more equipment with less manual intervention and troubleshooting.

- Material waste falls 10-20% through tighter process control and real-time quality feedback loops.

- Production throughput increases 15-30% by eliminating bottlenecks that only become visible with system-wide data visibility.

Return on Investment Accelerates Over Time: Initial integration projects typically pay for themselves within 18-24 months through direct cost reductions. The real value compounds in subsequent years as the foundation supports continuous improvement initiatives that weren’t possible with fragmented systems. Companies can add capabilities, scale production, or enter new markets without rebuilding their entire control infrastructure. This flexibility becomes a competitive advantage that’s difficult for rivals operating with legacy architectures to match.

Risk Mitigation Protects Future Performance: Beyond immediate savings, integration reduces exposure to several business risks. Regulatory compliance becomes easier when audit trails flow automatically from production to documentation systems. Cybersecurity strengthens when fewer connection points require monitoring. Business continuity improves because integrated systems are easier to backup, simulate, and restore after disruptions. These protective benefits may not generate direct revenue, but they prevent costly incidents that can erase years of operational gains.

Conclusion

Automation integration represents more than a technical upgrade; it’s a fundamental shift in how manufacturing operations create value. The difference between reactive maintenance and predictive optimization, between siloed data and actionable intelligence, determines whether facilities compete on cost or struggle to stay viable. Companies that treat integration as a strategic business investment position themselves to adapt quickly as markets shift and technologies evolve. If hidden costs are eroding your profitability, a comprehensive assessment of your control system architecture could reveal opportunities that transform your operational economics.